Polymeric and Ceramic Membranes

Aqua-Aerobic Systems provides two types of Aqua MultiBore® membranes, polymeric and ceramic. The type of membrane used in an application is dependent on waste characteristics, treatment objectives and the best economic solution for the plant.

Aqua MultiBore® P-Series

Polymeric Membranes

The Aqua MultiBore polymeric membrane has been successfully applied in both water and wastewater including high solids applications.

How It Works

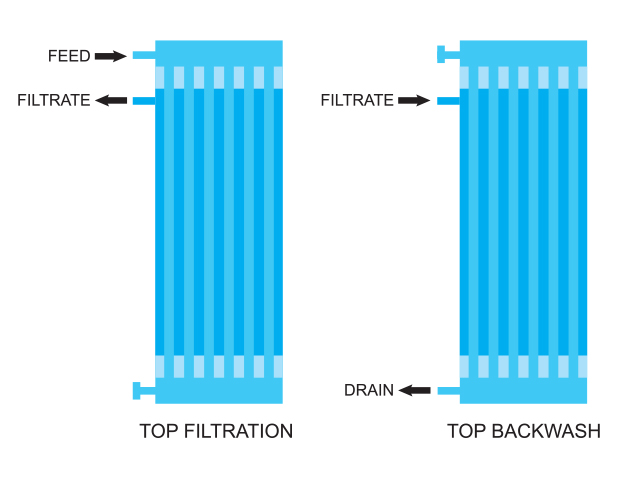

Filtration Mode

- During top filtration, influent enters the top of each membrane module and flows down through each fiber bore

- The 0.02 µ pores allow water to pass through to the outside of the fiber but retain suspended solids, bacteria, cysts, and viruses

- During bottom filtration, influent enters the bottom of each module and flows up through the fiber bores

- The system alternates between top and bottom filtration to evenly distribute impurities along the entire fiber length

- In both filtration modes, filtered water flows from the outside of the fibers through the filtrate port on the side of the module

Backwash Mode

- During both the top and bottom backwash modes, filtered water enters the filtrate port on the side of each membrane module and flows into each fiber

- During top backwash, water flows down through the fiber bores, into the bottom of the module and out to drain

- During bottom backwash, water flows up through the fiber bores, into the top of the module and out to drain

- The system alternates between top and bottom backwash so that impurities collected at both module ends can be efficiently flushed out

- Backwash occurs every 20 – 80 minutes, depending on influent quality

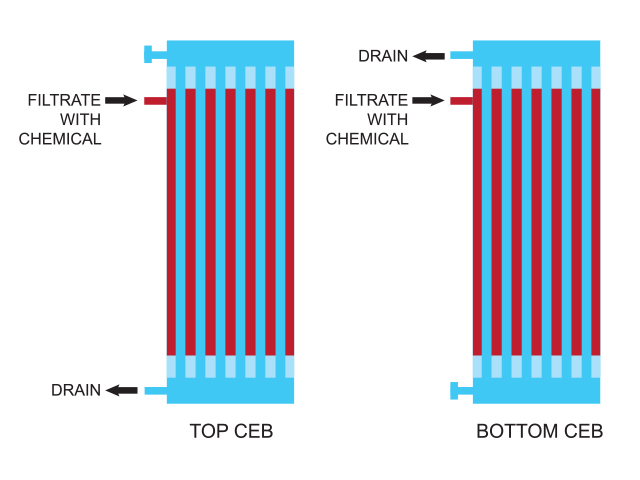

Chemically-Enhanced Backwash (CEB) Mode

- Chemicals are periodically added to the backwash water to dissolve any impurities that were not removed during the backwash modes

- The flow paths are the same as during backwash, only small amounts of chemical are injected into the filtrate prior to entering the modules

- Caustic is used to dissolve organics, acid is used to dissolve inorganic matter, and chlorine is used for occasional disinfection

- The membranes are soaked in the chemical for 10-20 minutes before being flushed out

- A CEB is performed every 8 -168 hours, depending on influent quality

Features & Specifications

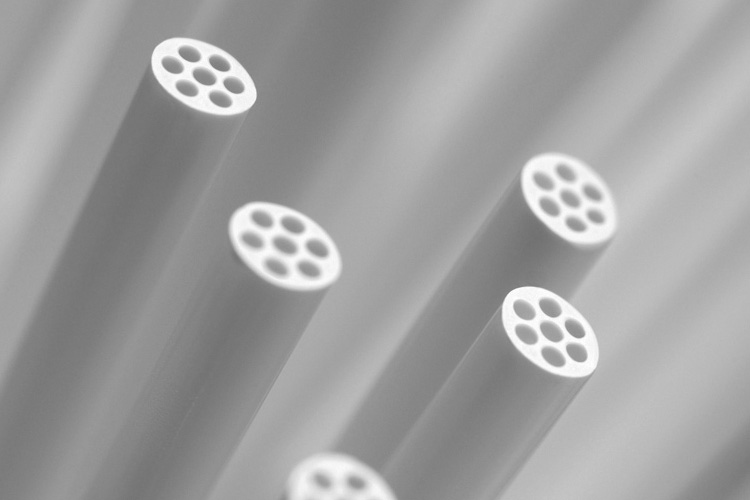

- Large diameter bores

- 0.02 μ UF membrane is rated for 4 log virus removal

- Each fiber is made from one material in a single process

- Inside-outside flow path requires no air scour

- Low fouling, can be cleaned with wide pH range (1-13)

- Superior strength – No fiber breaks!

Benefits

- Less chemical usage

- High water recover rate

- Low energy consumption

- High Permeability

- No basins or lifting equipment required

- Simple operation and low maintenance

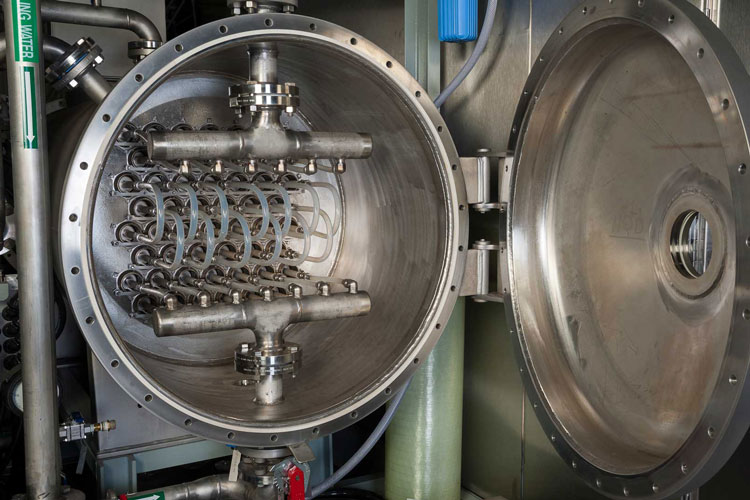

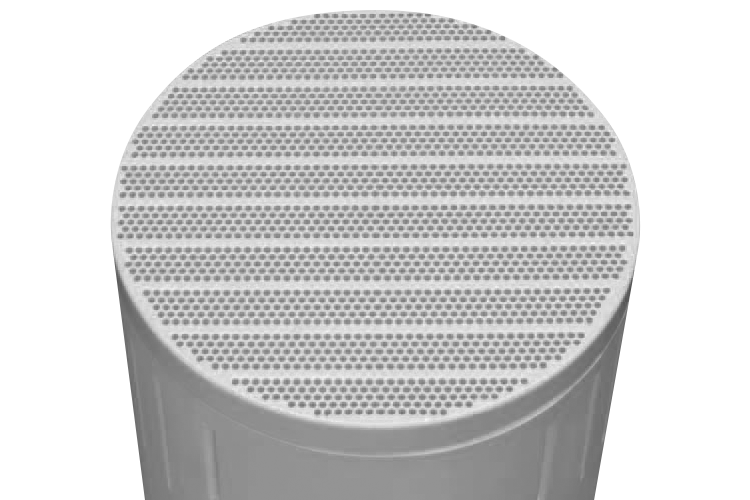

Aqua MultiBore® C-Series

Ceramic Membranes

The Aqua MultiBore® C-Series ceramic membranes have been successfully applied in both water and wastewater applications with more than 140 installed systems from pretreatment to advanced treatment of drinking water.

How It Works

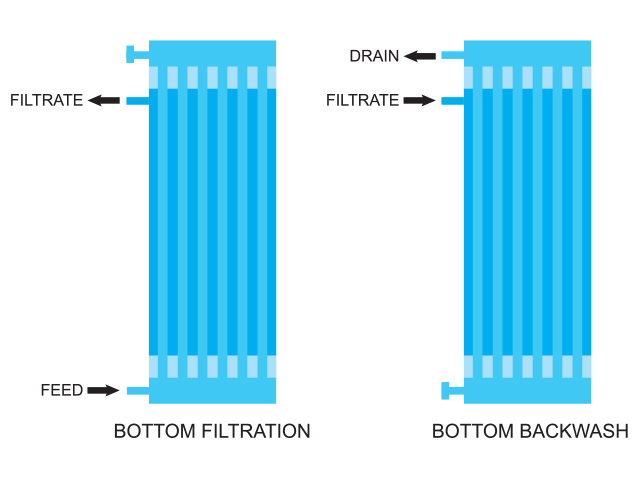

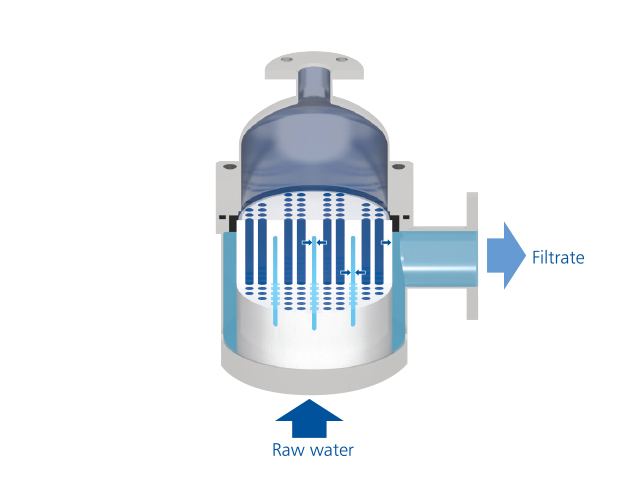

Filtration Mode

- During filtration, influent enters from the bottom of each membrane module and flows up through each ceramic filtration cell

- The 0.1 µ pores allow water to pass through to the ceramic filtrate collection cells

- Collected filtrate then exits the membrane through the filtrate port on the side of the module

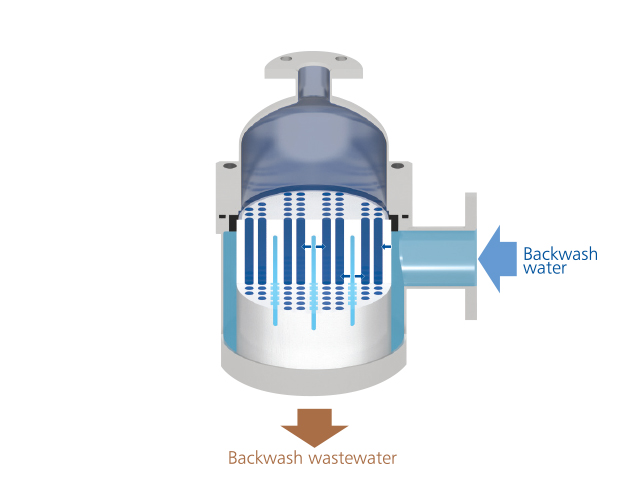

Backwash Mode

- During backwash, filtered water enters the filtrate port on the side of each membrane module and flows into each filtration cell

- 70 psi filtrate detaches fouling matter within the filtration cells

- Most impurities are collected at the bottom of the module and efficiently flushed out

- Typical backwash occurs every 4 to 12 hours

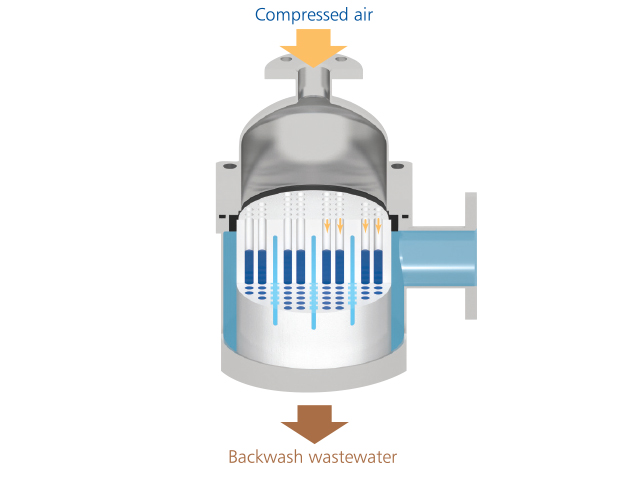

Airflush Mode

- Compressed air is injected into the top of the membrane sub-module to remove any remaining impurities that were not removed during the backwash mode

- Airflush typically takes 2-5 seconds at a maximum pressure of 30 psi

- The system is then placed back into normal filtration mode

Features & Specifications

- Membrane is constructed with very uniform 0.1 μ pores resulting in high fluxes

- Each ceramic membrane is made from one material in a single process

- Inside-outside flow path

- Resistant to pressure, heat and corrosion

- High mechanical strength – No membrane breaks!

- Low environmental impact – used membranes can be recycled

- Backwashed with a short blast of filtrate and air, resulting in very high recoveries

Benefits

- Less chemical usage

- High water recover rate

- Low energy consumption

- High Permeability

- No basins or lifting equipment required

- Simple operation and low maintenance

Aqua MultiBore Ceramic Membranes at Butte, MT

Plant Photos

Applications

Related Resources

| Resource Categories | Title | Summary | Download Link |

|---|---|---|---|

| Video | Aqua-Aerobic Systems, Inc. Overview Video | ||

| Success Story | Butler, MO | Butler WTP solves membrane integrity issues and meets EPA LT2 Rule with Aqua MultiBore® Membranes | |

| Success Story | Butte, MT | Aqua MultiBore® C-Series Ceramic Membrane System Solves Disinfection By-Product (DBP) Challenge at Butte-Silver Bow, Montana | |

| White Paper | Buxachatchee Paper | ||

| Video | Ceramic Membranes Solve Disinfection By-Product (DBP) Challenge at Butte, MT Water Plant | ||

| Brochure | Membrane Systems Brochure | ||

| White Paper | MultiBore C Series Butte, MT White Paper | FIRST ON-DEMAND POTABLE CERAMIC MEMBRANE SYSTEM IN U.S. MINIMIZES ENERGY AND WASTE | |

| White Paper | MultiBore P Series White Paper | NO-BREAK FIBER SOLVES MEMBRANE INTEGRITY PROBLEMS AT FIVE WATER TREATMENT PLANTS |